Out of all the decking options available to homeowners today. One of the most intriguing types of decking is WPC profile boards tongue and groove. They are typically used on porch planks. These wood or WPC decking may be used to create decks for outside areas.

Two items can be joined together using the tongue and groove profile approach. It dates back hundreds of years and is used now for porch floors and cabinetry. Even though this procedure can be done in a variety of ways. Any piece of wood having ridges on one edge and grooves on the other is referred to by this broad phrase.

What is WPC profile boards tongue and groove?

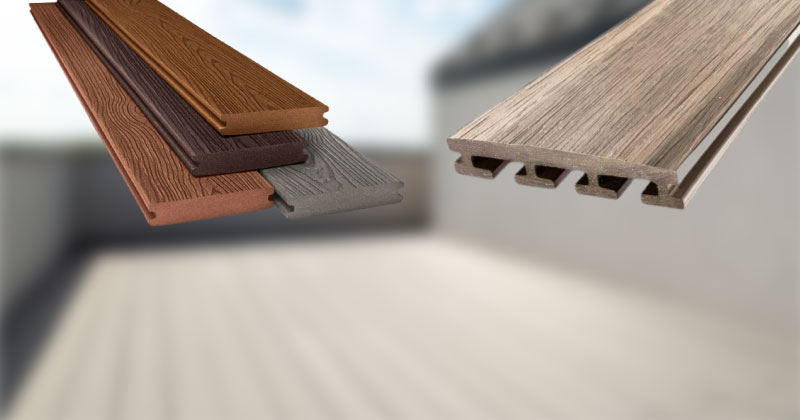

A groove is present along one edge of the wood or WPC planks that make up wpc profilbretter nut und feder. The tongue and groove of the dream deck is a lengthy groove on one side and a hump on the other. In order to fit tightly into the groove of the following plank, the tongue and groove profile is carved. The floor’s whole length is taken into account while cutting the tongue and groove. As a result, the planks may fit together to form a flat surface like puzzle pieces.

The objective is to create a beautiful, sturdy surface that looks like real wood throughout. As a result, tongue-and-groove installation structures will be more stable. The boards’ tongue-and-groove construction makes them ideal for a variety of applications, but porch flooring is where they are most frequently utilized. Although it may be used for decking, the majority of people build modest covered patios and porches with it.

Variety of tongue-and-groove decking types

Despite how widely used the tongue and groove technique is. It might be challenging to locate full-size decking planks when you need them. Additionally, it lacks several items that it might have. As a result, WPC panels with tongue and groove is available in both real and synthetic wood.

Pressure-treated wood dominates the market for WPC panels with tongue and groove, followed by cedar, redwood, and so forth. The greatest woods are those like ipe terrassendiele.

Pine and spruce tend to be the least expensive of these woods despite the fact that their prices and availability fluctuate. The costliest hardwood is ipe decking board, a tropical hardwood that resists insects and the effects of weather.

WPC decking is constructed from materials that cooperate. When making WPC decking, molds are used to create various sizes and shapes. WPC decking features tighter joints as a result, and unlike tongue-and-groove wood decking, it can be moved without the assistance of a hand truck.

To make WPC tongue-and-groove decking appear and feel like real wood, it typically contains some wood fibers. Polymer resins, recycled plastics, and polyvinyl chloride (PVC) are a few of the most popular synthetic materials. The cost of WPC decking produced from these components will be comparable to that of ipe decking board and pine decking.

The advantages of WPC decking with tongue and groove

WPC decking is advantageous since it lasts a long time and has a uniform appearance. Pine decking, for example, is made of natural wood and might distort during installation. However, WPC decking joined with a tongue and groove won’t absorb moisture or distort.

Another advantage of WPC decking composed of recycled plastic or polymers is the “green” usage of resources. Dangerous chemicals like formaldehyde are not present in WPC panels with tongue and groove. Additionally, it is effective in removing domestic waste like plastic. This prevents our toxic environment from growing worse.

Tongue and groove decking is typically used to create ornamental panels for porches. However, interior building roofs and ceilings can also be constructed using tongue and groove wood ornamental panels. Standard-width tongue-and-groove decking is used on the ceiling of a home or cabin to give it a rustic appearance rather than gypsum wallboard or other conventional materials.

You won’t typically find tongue-and-groove roof trim boards at home improvement stores since they are a more specialized kind of material. To make all-wood buildings, such timber frames or logs, appear and feel like they are made of wood, it is frequently utilized. The majority of tongue and groove roof trim panels are constructed from materials that are typically 2 to 4 inches thicker. Two sets of grooves with corresponding mortises and tenons can be present in tongue and groove roof trim panels.

Read More: 10 Reasons To Install An Outdoor Shower